In the realm of woodworking, precision is paramount, and the choice of tools can make all the difference. Among these tools, Miter Saw Blades plays a crucial role in achieving accurate cuts. For seasoned craftsmen, selecting the right blade is strategic, influencing the quality of their work. In this guide, we explore the types, sizes, and applications of miter saw blades. From crosscuts to finishes, each blade type serves a unique purpose. Join us as we delve into the essentials of blade selection, offering insights tailored to the discerning woodworker’s needs.

Understanding Miter Saw Blades

Definition and Purpose of a Miter Saw Blade

At its core, a miter saw blade is the cutting edge of precision in woodworking. Specifically designed for miter saws, these blades are engineered to make clean and accurate cuts at various angles, typically ranging from 90 degrees (straight cuts) to 45 degrees (miter cuts). The primary purpose of a miter saw blade is to facilitate precise crosscuts, bevel cuts, and compound cuts in wood, plastic, and even non-ferrous metals. Whether you’re framing a house or crafting intricate furniture pieces, the miter saw blade is your trusted companion, enabling you to execute intricate cuts with ease and efficiency.

Components of a Miter Saw Blade:

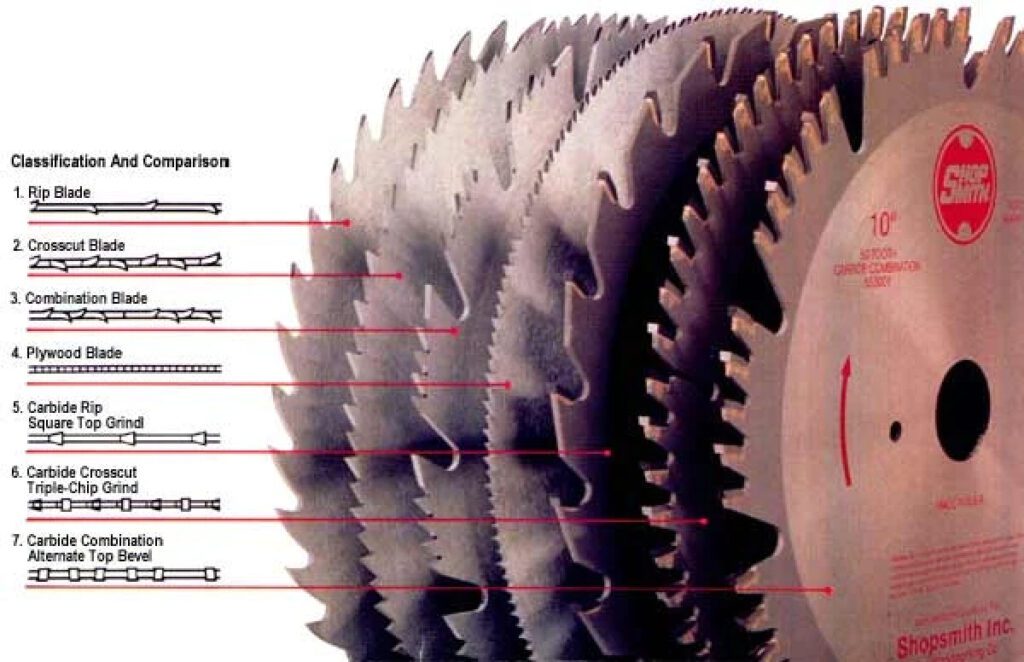

Comprehending the anatomy of a miter saw blade is key to understanding its functionality. A typical blade comprises several essential components, each contributing to its cutting performance. The blade’s body, usually made of high-carbon steel or carbide-tipped material, provides stability and rigidity during operation. Teeth, the sharp protrusions along the blade’s circumference, are responsible for cutting through the material. Tooth configurations vary based on the blade’s intended use, with options such as alternate top bevel (ATB), triple chip grind (TCG), and flat-top grind (FTG). Additionally, the gullet, the space between the teeth, facilitates chip removal, preventing overheating and maintaining cutting efficiency.

Importance of Blade Quality and Material:

When it comes to miter saw blades, quality and material matter significantly. Blades crafted from premium materials like carbide-tipped steel or high-speed steel offer enhanced durability, longevity, and cutting precision compared to their lower-quality counterparts. Investing in high-quality blades not only ensures cleaner cuts but also reduces the frequency of blade changes, saving time and resources in the long run. Furthermore, the choice of blade material depends on the specific application and the type of material being cut. While carbide-tipped blades excel in cutting hardwoods and abrasive materials. In essence, prioritizing blade quality and material selection is indispensable for achieving optimal cutting performance and maximizing the lifespan of your miter saw.

Maintenance and Care of Miter Saw Blades

Importance of Blade Maintenance:

Proper maintenance of miter saw blades is essential for ensuring optimal cutting performance, prolonging blade life, and achieving professional-quality results. Over time, blades can accumulate pitch, resin, and debris, which can diminish cutting efficiency and increase the risk of overheating and blade deflection. Regular maintenance helps prevent these issues and keeps your blades in peak condition for smooth and precise cuts.

Tips for Cleaning and Sharpening Miter Saw Blades:

Cleaning miter saw blades regularly is the first step in maintaining their performance. Remove built-up pitch and resin deposits using a blade cleaning solution or a solvent specifically designed for cutting tools. Additionally, periodic sharpening helps restore the sharpness of dull blades and prolongs their cutting life. Use a diamond file, sharpening stone, or dedicated blade sharpener to hone the teeth to their original sharpness. Be sure to follow the manufacturer’s recommendations and proper sharpening techniques to avoid damaging the blade.

Storing Blades Properly to Extend Their Lifespan:

Proper storage is crucial for preserving the integrity and sharpness of miter saw blades when not in use. Store blades in a dry and climate-controlled environment to prevent corrosion and rust formation. Avoid storing blades in damp or humid conditions, as moisture can accelerate blade degradation and compromise cutting performance. Additionally, consider using blade covers or protective cases to shield blades from dust, debris, and accidental damage during storage. By storing blades properly, you can extend their lifespan and maintain their cutting precision for years to come.

Types of Miter Saw Blades

Crosscut Blades:

- Crosscut blades are distinguished by their configuration of alternating top bevel (ATB) teeth, which are angled to slice cleanly across wood fibers without tearing or splintering. These blades typically feature a higher tooth count, ranging from 60 to 100 teeth per blade, ensuring precise and smooth cuts across the grain of the wood.

- Ideal for making clean and accurate cuts on hardwoods, softwoods, plywood, and veneers, crosscut blades excel in applications where smooth edges and minimal tear-out are paramount. Whether you’re crafting furniture, trim work, or intricate joinery, these blades deliver exceptional results, leaving behind polished surfaces ready for assembly or finishing.

Combination Blades:

- Combination blades are designed with a versatile tooth configuration that incorporates both flat-top grind (FTG) and alternate top bevel (ATB) teeth. This hybrid design enables them to tackle a wide range of cutting tasks, from crosscutting to ripping, with equal proficiency. With a balanced combination of teeth, these blades offer the best of both worlds: aggressive cutting action and clean finishes.

- Renowned for their versatility, combination blades are suitable for cutting various materials, including hardwoods, softwoods, plywood, and even some non-ferrous metals like aluminum and brass. Whether you’re framing a house, building cabinets, or fabricating metal components, these blades provide reliable performance across diverse applications, making them indispensable in any woodworking or metalworking shop.

Fine Finish Blades:

- Fine finish blades are characterized by their high tooth count and precision-engineered tooth geometry, featuring alternate top bevel (ATB) or triple chip grind (TCG) teeth. These blades are specifically crafted to produce ultra-smooth, splinter-free cuts with minimal tear-out, leaving behind flawless surfaces that require minimal sanding or surface preparation.

- Ideal for applications that demand impeccable surface quality, such as cabinetry, furniture making, and trim work, fine finish blades excel in achieving professional-grade results with exceptional clarity and precision. Whether you’re working with hardwoods, veneers, laminates, or melamine, these blades elevate the aesthetic appeal of your projects, ensuring that every cut is a testament to your craftsmanship.

Miter Saw Blade Sizes

Common Blade Diameters for Miter Saws:

Miter saw blades come in a variety of diameters, with common sizes ranging from 7-1/4 inches to 12 inches. The most prevalent sizes among miter saws are 10 inches and 12 inches, offering a balance between cutting capacity and portability. Smaller diameter blades, such as 7-1/4 inches, are typically found on compact miter saws and are suitable for light-duty cutting tasks, while larger blades provide increased cutting depth and versatility for handling thicker stock and larger workpieces.

Understanding Tooth Count and Configuration:

The tooth count and configuration of a miter saw blade play a pivotal role in its cutting performance and versatility. Blades with higher tooth counts, such as 80 to 100 teeth, are ideal for achieving smooth and precise cuts on fine woodworking projects, as they produce minimal tear-out and splintering. Conversely, blades with lower tooth counts, typically ranging from 24 to 40 teeth, are better suited for rough carpentry and fast cutting tasks, as they offer aggressive material removal and reduced cutting resistance. Additionally, the tooth configuration, whether it’s alternate top bevel (ATB), triple chip grind (TCG), or flat-top grind (FTG), influences the blade’s cutting action and application suitability.

How Blade Size Affects Cutting Capacity and Performance:

Blade size directly impacts a miter saw’s cutting capacity and performance, dictating the maximum thickness and width of the material that can be cut. Larger diameter blades, such as 12 inches, offer greater cutting depth and capacity, allowing users to tackle thicker stock and larger workpieces with ease. Additionally, larger blades generate higher linear blade speeds, resulting in smoother cuts and reduced vibration during operation. However, it’s essential to match the blade size to the specifications of your miter saw, ensuring compatibility and optimal performance. Ultimately, selecting the right blade size involves considering the specific cutting requirements of your project and balancing them with the capabilities of your miter saw.

Selecting the Right Blade for the Job

Factors to Consider When Choosing a Miter Saw Blade:

- When selecting a miter saw blade, it’s crucial to consider the material being cut. Different blade types and tooth configurations are optimized for specific materials, such as wood, plastic, and non-ferrous metals. Choosing the right blade ensures clean cuts and prolongs blade life.

- Another critical factor is the cutting accuracy required for the project. Fine woodworking and finish carpentry demand blades with higher tooth counts and precision tooth geometry to achieve smooth, splinter-free cuts. Conversely, rough carpentry and framing may prioritize speed and material removal over surface finish.

- Budget and blade longevity also play a significant role in blade selection. While high-quality blades may come with a higher upfront cost, they often offer superior performance and longer service life, resulting in cost savings over time. However, it’s essential to balance budget considerations with the specific needs of the project to make an informed decision.

Tips for Matching the Blade to the Project:

Consider the thickness and type of material you’ll be cutting, as well as the desired cut quality and finish. For fine woodworking and detailed joinery, opt for blades with higher tooth counts and precision tooth geometry. Conversely, for rough carpentry and fast cutting tasks, choose blades with lower tooth counts and aggressive tooth configurations. Additionally, ensure that the blade size and arbor compatibility match your miter saw’s specifications to prevent safety hazards and optimize cutting performance.

Safety Considerations When Selecting and Using Miter Saw Blades:

Always prioritize safety when selecting and using miter saw blades. Choose blades that are appropriate for the material and application to minimize the risk of kickback, binding, and blade deflection. Ensure that the blade is securely mounted and properly aligned with the miter saw’s arbor to prevent accidents during operation. Additionally, wear appropriate personal protective equipment, such as safety glasses, hearing protection, and dust masks, to safeguard against flying debris and harmful dust particles. Finally, follow manufacturer guidelines and best practices for blade installation, maintenance, and operation to ensure safe and efficient use of your miter saw.

Wrapping Up Our Thoughts About Miter Saw Blades

In closing, understanding miter saw blades is foundational to the craft of woodworking, offering craftsmen the precision, efficiency, and versatility needed to bring their projects to fruition. From selecting the right blade for the job to maintaining its peak performance, the journey of mastering miter saw blades is both an art and a science. As you embark on your woodworking endeavors, may you apply the insights gained here with diligence and enthusiasm, transforming raw materials into works of art that reflect your passion and skill. Let your projects be a testament to the craftsmanship and creativity that define the art of woodworking, and may each cut be a step toward mastery and fulfillment in your craft.